SUMMARY

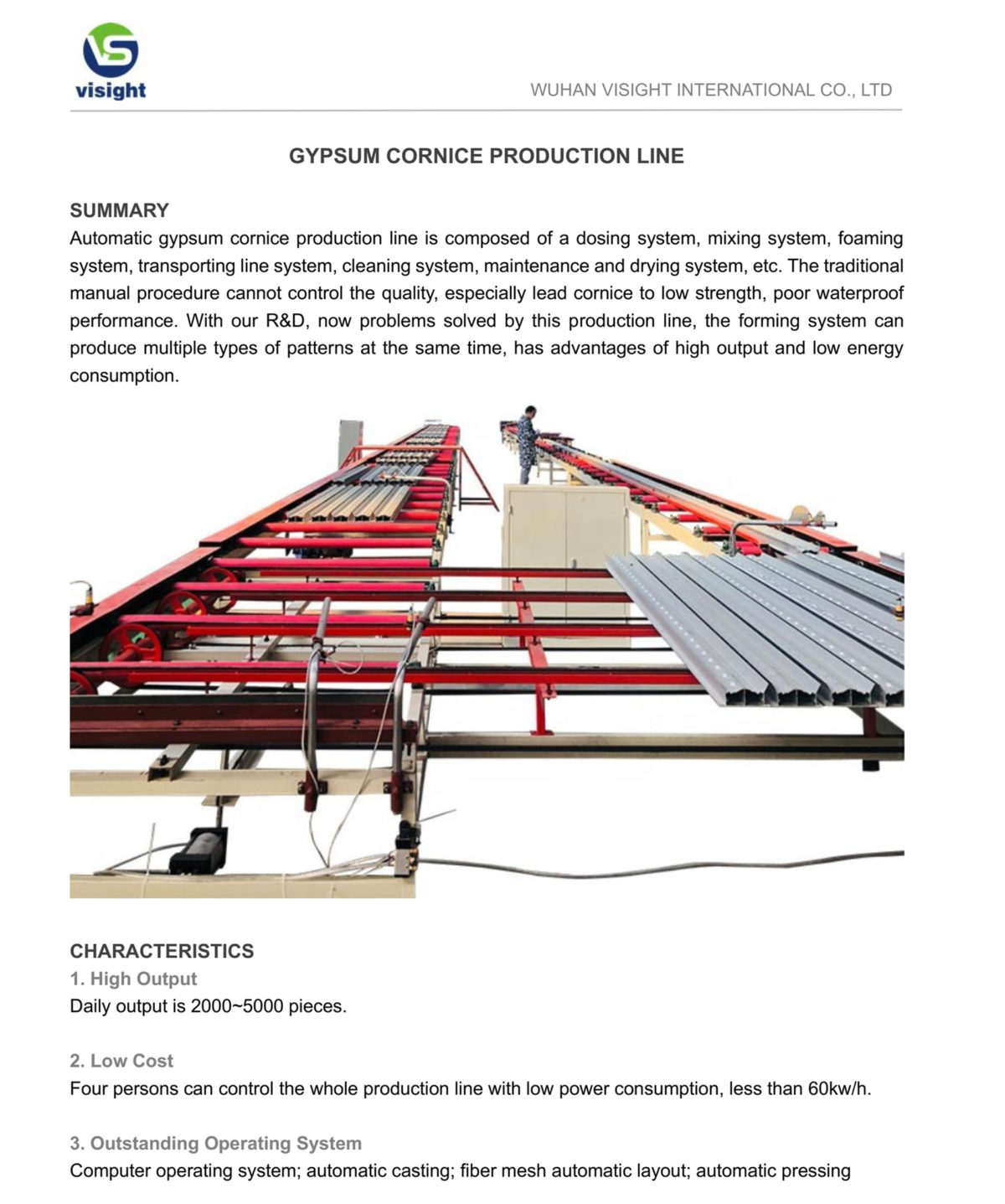

Automatic gypsum cornice production line is composed of a dosing system, mixing system, foaming system, transporting line system, cleaning system, maintenance and drying system, etc. The traditional manual procedure cannot control the quality, especially lead cornice to low strength, poor waterproof performance. With our R&D, now problems solved by this production line, the forming system can produce multiple types of patterns at the same time, has advantages of high output and low energy consumption.

CHARACTERISTICS

1. High Output

Daily output is 2000~5000 pieces.

2. Low Cost

Four persons can control the whole production line with low power consumption, less than 60kw/h.

3. Outstanding Operating System

Computer operating system; automatic casting; fiber mesh automatic layout; automatic pressing

4. High Quality Cornice

The finished cornice is with high polished, delicate and beautiful appearance

5. OEM Service

There are three standard models for customers’ reference, it can be customized as your requirements.

6. High Efficiency

Daily output 5000~30000m, production line is 45~160m.