1. The Function of Gypsum Board Adhesive

The production and molding of the gypsum board is the bonding of gypsum board surface paper and gypsum slurry. The surface paper must be firmly bonded to the gypsum board core, so that the gypsum board has a specific strength. The effect and performance of the adhesive are significantly important in the gypsum board products.

When the gypsum board face paper is bonded with the gypsum slurry, the infiltration and diffusion of water, the gypsum supersaturated liquid and the bonding agent penetrate the paper tissue together. And the gypsum also generates needle-like crystals, which are combined with the bonding agent in the vertical and horizontal directions of the face paper. It is tightly combined to form a network structure, and the gypsum slurry is firmly bonded to the tissue through the adhesive.

The adhesive also acts as a protective film to prevent moisture in the air from immersing into the gypsum board core, and to prevent the gypsum board core from getting damp and separating from the tissue. The firm bonding between the tissue paper and the gypsum board core acts as a reinforcement in the solidified gypsum, which enhances the compressive strength and flexural strength of the gypsum board.

2. Requirements for Gypsum Board Adhesive

Gypsum board adhesive should be rich in resources with low price. It is required that the gypsum board surface paper and the gypsum board core have good bonding performance, and the relative amount of bonding agent is small. It is required to have migration properties that can migrate from the gypsum board core to the surface layer, so that the added bonding agent migrates to the board core bonding layer, and the bonding agent plays the role of bonding the board core and the facial paper. The gypsum board bonding agent is easily soluble in water at room temperature. When the temperature rises, the viscosity does not rise fast, and when the temperature drops, the viscosity increases and also the bonding force.

3. Selection of Gypsum Board Adhesive

In the process of research and test of gypsum board, a variety of adhesives, such as polyvinyl alcohol, were used. In the production process of gypsum board, polyvinyl alcohol has a good bonding effect, and the produced gypsum board is also powerful, but polyvinyl alcohol has no migration effect in the gypsum board core, only bonding. It is relatively evenly distributed in the gypsum board core and does not penetrate between the tissue paper and the gypsum board core, so the mixing amount is also large. Besides, polyvinyl alcohol is expensive, resulting in high production costs for gypsum board.

They were taking tests for starches, acorn flour, tapioca starch and corn starch. All the above starch meets the requirements, but corn starch has the best result. Starch is a carbohydrate polysaccharide polymer, and the molecular formula is (C6H10O5)n. The number of monosaccharide chains is usually around 50,000, but some can reach millions. The natural corn starch is gelatinized when heated to 60°C and has a certain degree of binding power, but it has no mobility and is not suitable for use as a binding agent.

In the process of acid treatment, starch can undergo incomplete hydrolysis. The acid acts on the glycosidic bond to hydrolyze the starch molecules, the starch molecular chains are broken, and the starch molecules become smaller and become dextrin. Dextrin has fewer molecular chains, usually only a few dozen starch sugar molecular chains. The migration of dextrin in the gypsum board core is excellent, but it is easy to migrate to the outside of the tissue paper and affect the adhesion between the tissue paper and the gypsum board core, and the bonding of dextrin itself is not strong. Tests show that it is also not suitable as a gypsum board adhesive. Modified starch is also an incomplete hydrolysis product of starch. Its starch sugar molecular chain number is less than that of natural starch, and more than dextrin, usually between several hundred to several thousand. When the modified starch is heated, its viscosity gradually rises. When it is cooled, the viscosity of the modified starch increases slowly, the viscosity changes smoothly, and the final binding force is more remarkable.

The migration properties of modified starch can be well controlled. Most of the modified starch is migrated to the interface between the gypsum board core and paper. There is very little modified starch left in the gypsum board core. Similarly, it migrates into the paper. The amount of modified starch is also small. In the production process of gypsum board, adding less modified starch can firmly bond the gypsum board core and the surface paper together, which is an ideal gypsum board adhesive.

4. The Production Process of Modified Starch

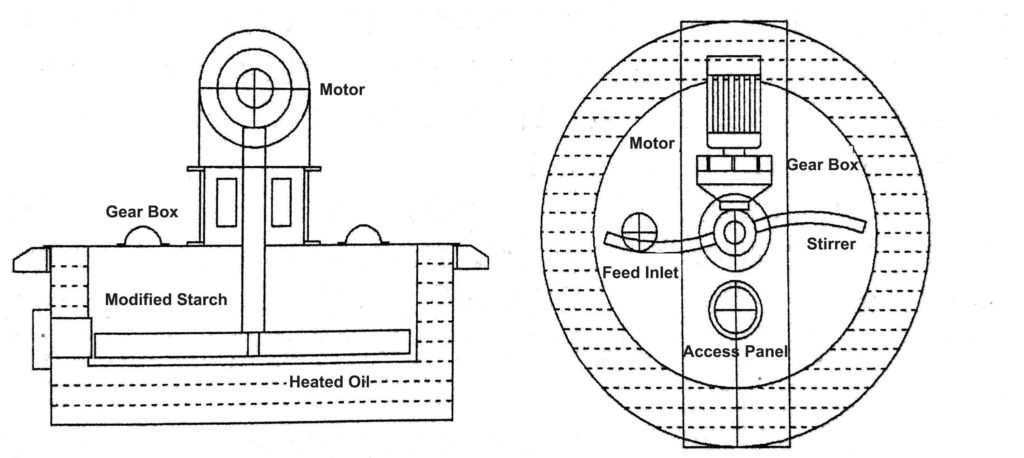

Natural corn starch usually contains 10% to 12% moisture. In the modified starch factory, the corn starch is slightly dried and all passed through a 120-mesh sieve. Spray 0.3% hydrochloric acid alcohol solution as a catalyst, dilute the hydrochloric acid with an appropriate amount of anhydrous alcohol in advance, stir it evenly in a sealed mixer, and age for 2 hours to fully acidify the corn starch. The starch added with a hydrochloric acid alcohol solution is heated and acidified in an oil bath. The acidified starch in the oil bath is slowly heated, and the heating rate is controlled at 1°C/min. When the temperature reaches about 130°C, heat preservation and heating for 30 minutes, and then quickly cool to room temperature to obtain modified starch. The modified starch oil bath equipment is shown in the figure. The modified starch process is as follows:

Starch → drying → sieving → acidification → stirring → aging → heating → modification → cooling → packaging → modified starch

Remark: Filled 38# cylinder oil into oil path pan, temperature 260℃,shaft rotation speed 31r/min.

5. Technical Indicators of Adhesive

Viscosity test conditions: The starch is formulated into a solution with a concentration of 12%, heated to 95°C while stirring, and then cooled to 25-30°C, and the viscosity is measured with a rotary viscometer. Its technical indicators are shown in the table below:

|

Item |

Parameter |

Item |

Parameter |

|---|---|---|---|

|

Starch Content |

≥75% |

Ash Content |

0.2% |

| Appearance | White Powder | Solubility | 73~78% @ 20~40℃ water |

| Protein | 0.3% | Viscosity | 50~100Pa•s |

| pH | 6.5~7.5 | Moisture | 8%~11% |