EPS Beads Making Machine

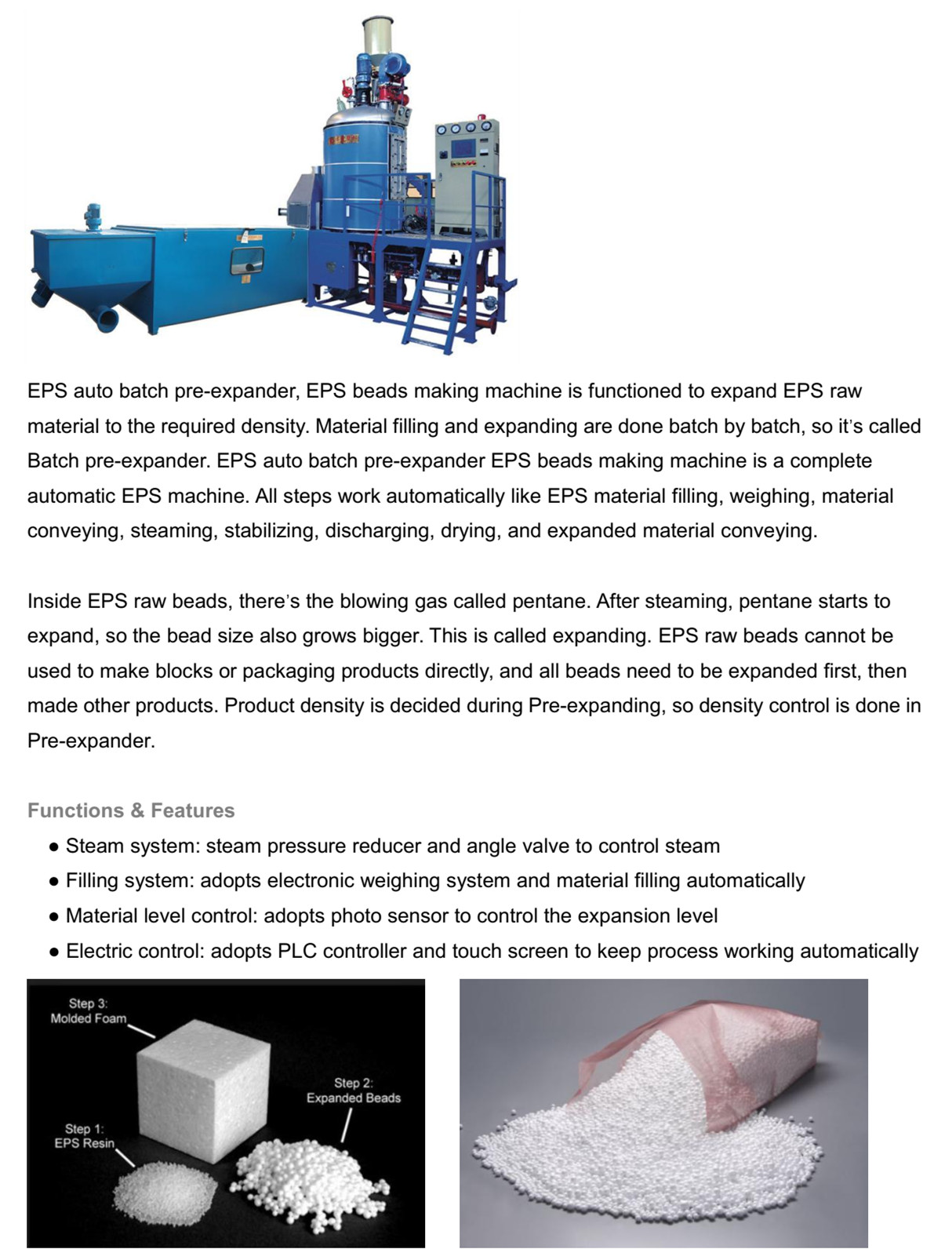

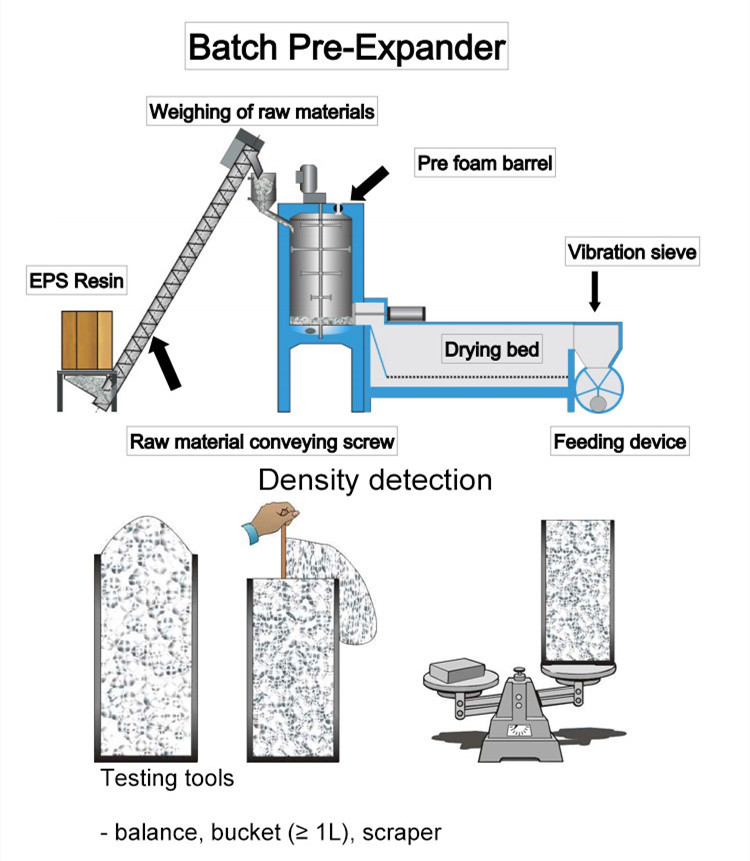

EPS auto batch pre-expander, EPS beads making machine is functioned to expand EPS raw material to the required density. Material filling and expanding are done batch by batch, so it’s called Batch pre-expander. EPS auto batch pre-expander EPS beads making machine is a complete automatic EPS machine. All steps work automatically like EPS material filling, weighing, material conveying, steaming, stabilizing, discharging, drying, and expanded material conveying.

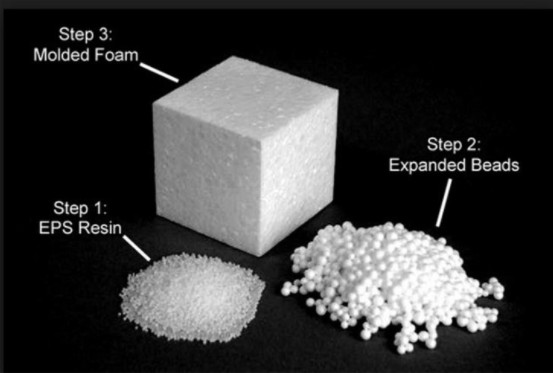

Inside EPS raw beads, there’s the blowing gas called pentane. After steaming, pentane starts to expand, so the bead size also grows bigger. This is called expanding. EPS raw beads cannot be used to make blocks or packaging products directly, and all beads need to be expanded first, then made other products. Product density is decided during Pre-expanding, so density control is done in Pre-expander.

Functions & Features

● Steam system: steam pressure reducer and angle valve to control steam

● Filling system: adopts electronic weighing system and material filling automatically

● Material level control: adopts photo sensor to control the expansion level

● Electric control: adopts PLC controller and touch screen to keep the process working automatically

Preheating

Open the cleaning door to remove the impurities in the cylinder, check whether the movable mixing rod is firm, and then close the cleaning door. Close the three valves on the control panel and close the feed gate. Start the mixing and feeding motor, and the mixing rod and feeding screw are idly running. At this time, open the steam valve to raise the temperature in the foaming cylinder to 70 ~ 75 ° C and keep it for 3 ~ 5 minutes.

Test Method

– Sampling location and time

– Outlet of fluidized bed and curing silo

– Density changes before and after ripening

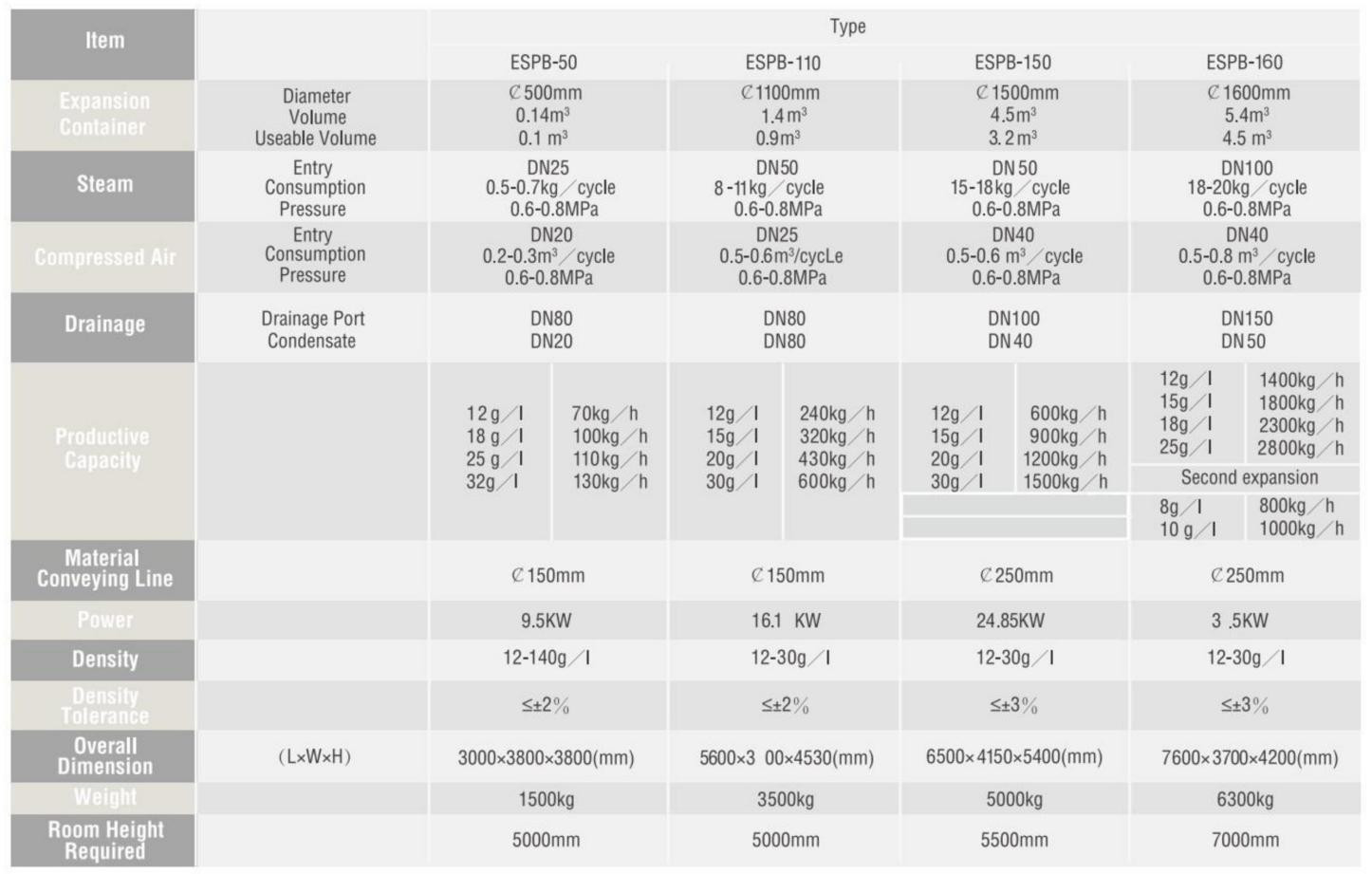

Technical Data

Product Features

1. Five safety protection devices with safety maintenance;

2. Adopts touch screen and plc control with easy operation;

3. The barrel material of the pre-expander is 304 stainless steel;

4. High-density rock wool is used as a thermal insulation layer, which can effectively reduce the temperature change;

5. Japanese reducing valve to control the steam pressure and make it stable and uniform;

6. Accurate weighing sensor to ensure the density difference between each batch;

7. The constant temperature and pressure guarantee foaming error within 3%;

8. The secondary foaming system to produce EPS products with lower density;

9. The fluidized bed is equipped with a particular drying system to reduce the ageing time of beads in the silo;

10. Branded low voltage electrical components.